INSIGHTS

INSIGHTS

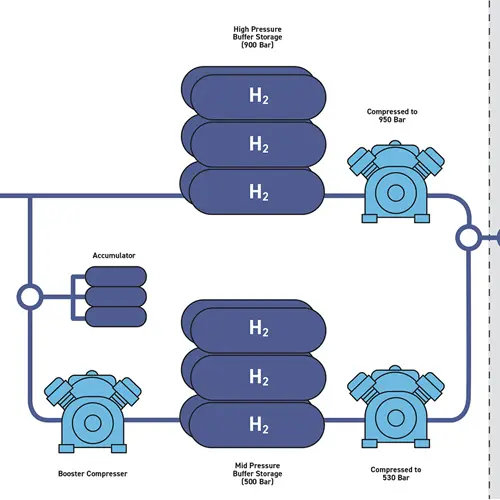

Tempco has already implemented numerous cooling and temperature control applications in the process industry that take advantage of the unique characteristics and performances of PCHE exchangers. From hydrogen refueling stations for green and sustainable mobility, to zero-emission railway and naval sectors, here are some of the applications described in our corporate Tempco Blog.

Innovative welding process that allows two metals to be joined through a kind of interpenetration of the crystalline structure of…

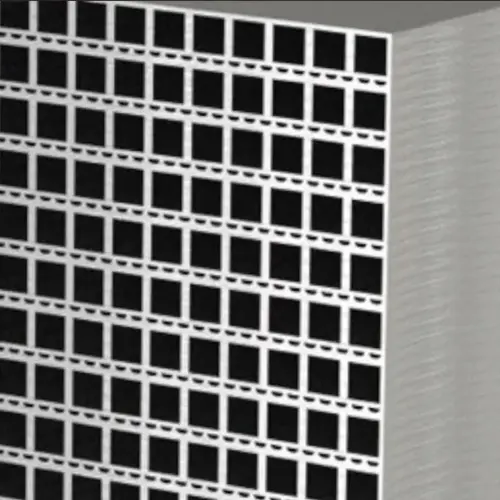

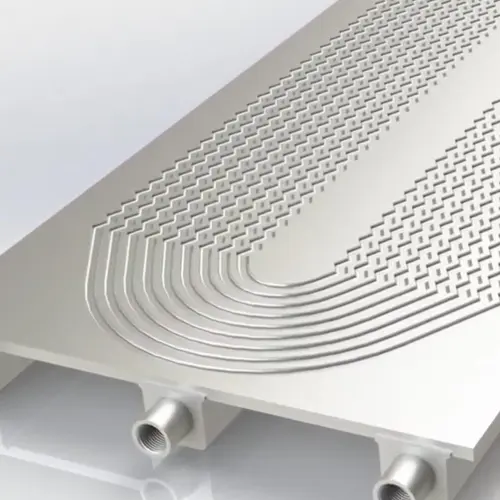

Exchangers made using technology similar in many respects to that used for printed circuit boards in electronics…

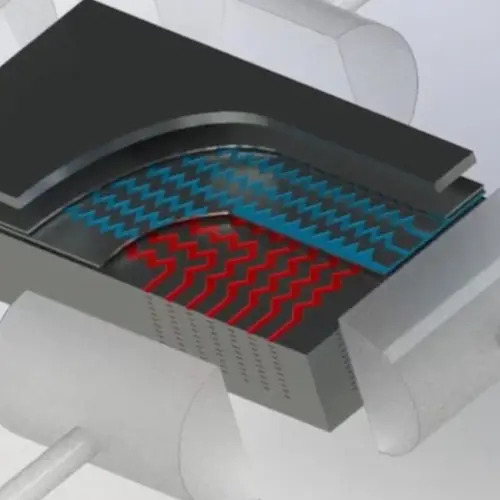

Use of multi-stram heat exchangers in hydrogen cooling between compression and distribution process steps…

Introduction to MICROCHANNEL DEVICES (µCD), Tempco’s technology partner, which manufactures the special PCHE exchangers using the Diffusion Bonding process…

The importance of PCHE exchangers used in hydrogen refuelling stations for vehicle mobility…

PCHE heat exchangers, (Printed circuit heat exchangers), are the flagship innovation with which Tempco will be exhibiting with technology partner…